Phosphate Fertilizers

Sulfuric Acid – General Valve Considerations

Sulfuric acid services introduce various technical challenges such as: mixed phases liquid/gas , high temperature, different corrosion levels, and sometimes abrasive suspended solids.

Wherever temperature and abrasion challenges are not present, Teflon-lined solutions are preferred so that economic body shell material can be used.

Otherwise, high alloy steel is sometimes the recommended option to handle extreme corrosion at slightly elevated temperature or when corrosion is coupled with the presence of abrasive suspended solids.

Teflon-lined Valves

Our selected partner manufacture high quality Teflon lined valves with dense Teflon lining and excellent adherence between the Teflon lining and metal body.

Teflon lined valves and other solutions can save Sulfuric acid production projects hundreds of thousands of dollars as they provide a viable alternative for expensive high alloy steel valves and other solutions.

Valves for Molten SULFUR & SO2/SO3

Large sizes (≥ 8”)

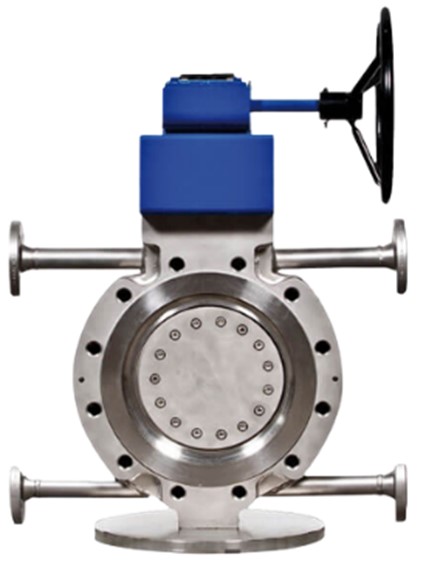

For sizes larger than 6” or 8”, butterfly valves are typical solutions for controlling the flow of molten Sulfur in pipes. Jacketed triple offset metal seated butterfly valves are widely used, but they face frequent jamming and valve malfunction due to the accumulation of crystalized Sulfur where steam heating does not reach, such as on the valve disc (at 3 and 9 o’clock positions, when valve is in the open position) as well as at the valve stem in the bearing area. Steam Traced & Jacketed high performance butterfly valves (HPBV STJ) are the ultimate solution for Sulfur contaminated media because steam heating reaches literally everywhere Sulfur reaches within the valve. Frequent valve jamming and associated problems are eliminated with HPBV STJ.

Metal Seated Triple Offset Butterfly Valves are typical for high temp. SO2/SO3 Gas.

Small sizes (≤ 6”)

Steam jacketed plug & ball valves are used economically & feasibly for small sizes, and up to 6” / DN150 or even 8” / DN200 size typically. Plug valves have the advantage of cavity free design, which increases the valve tolerance to crystalized Sulfur in case of short heating steam cuts.

Globe & Gate Valves

Gate & Globe Valves continue to play a big role in Sulfuric acid plants, even after far better solutions have been developed for specific Sulfuric acid services. This is due to their robustness, long service lives. However, they are known for their imperfected internal leakage and emission control; except for bellows sealed valves.